Thermal Printing Paper is an essential component in the world of printing technology. It is used in various applications, from receipts to labels. Its unique ability to create images without the need for ink makes it a fascinating topic of discussion.

Understanding how Thermal Printing Paper works can deeply enhance its practical use. The process involves heat-sensitive coatings, which react to a thermal print head. This interaction triggers a chemical change in the paper, producing visible images. Yet, this seemingly simple mechanism raises questions about durability and environmental impact.

While Thermal Printing Paper offers convenience, it can also present challenges. For instance, it may fade over time when exposed to light or heat. Additionally, the production of this paper may not always consider sustainability. Exploring these elements is essential for anyone utilizing Thermal Printing Paper in their work.

Thermal printing paper is a special type of paper used primarily in thermal printers. This paper has a unique coating that reacts to heat. When heated, it produces an image or text. Unlike traditional printing, it doesn’t require ink or toner. This can seem like magic, but the science is quite fascinating.

The coating on thermal paper contains dye and a stable, colorless chemical. When exposed to heat, the dye becomes visible and creates a printed image. This method is quick and efficient. However, there are downsides. Thermal prints can fade over time, especially with exposure to light or heat. The paper can also be sensitive to certain chemicals. These factors can affect the longevity of printed documents.

Using thermal paper can feel like a double-edged sword. On one hand, it simplifies the printing process. On the other hand, the durability issue raises concerns for important documents. Therefore, understanding its properties is crucial. Many users may overlook these details, but it’s essential for effective use. Balancing convenience with quality can lead to better decisions in printing practices.

| Property | Description |

|---|---|

| Material | Thermal printing paper is typically made from a base of paper or synthetic materials coated with a thermal coating. |

| Functionality | It reacts to heat from print heads to create images or texts, eliminating the need for ink or toner. |

| Applications | Common applications include label printing, receipts, tickets, and barcodes. |

| Advantages | Cost-effective, fast printing speed, and no need for ink supplies. |

| Disadvantages | Sensitive to heat and light, which may cause fading or discoloration over time. |

| Storage Conditions | Should be stored in a cool, dry place away from direct sunlight to maintain quality. |

| Printing Principle | Uses thermal transfer or direct thermal printing methods to create an image by applying heat. |

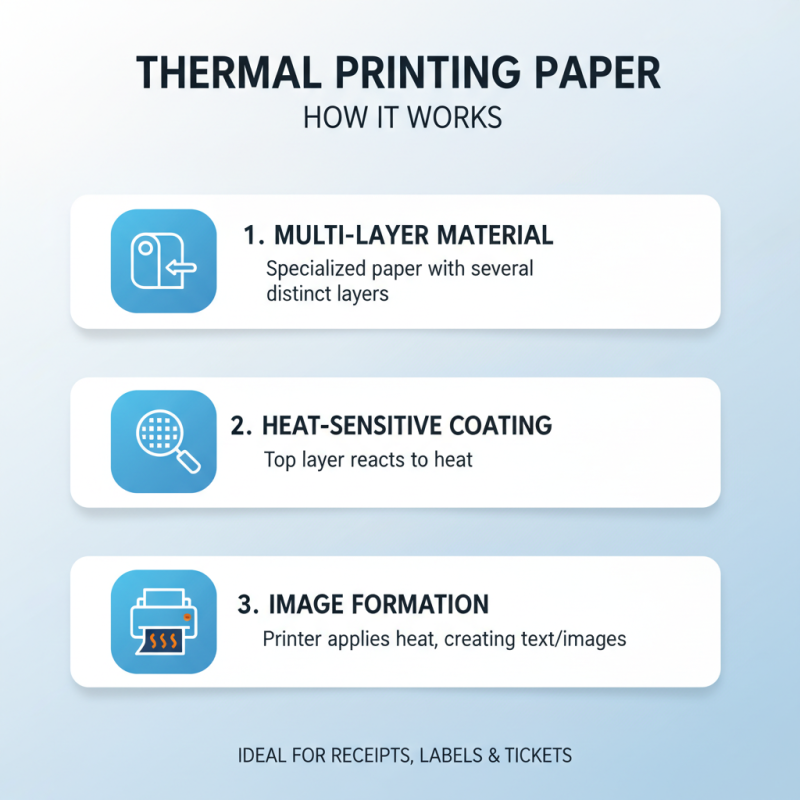

Thermal printing paper is a specialized material used in thermal printers. It consists of multiple layers, each serving a unique purpose. The top layer contains a heat-sensitive coating. This coating reacts to heat and creates images or text when the printer applies heat.

The base of thermal paper usually consists of a base sheet made from a substance like wood pulp or plastic. A special coating is applied to this base. The coating typically contains dye or pigment particles. When heated, these particles change color, resulting in printed images. The paper's composition can affect the final print quality. Factors such as thickness and layer quality come into play.

However, not all thermal papers are created equal. Some may degrade faster than others, affecting longevity. Additionally, consistent exposure to light or heat can compromise print clarity over time. Users might notice differences in performance based on varying environmental conditions. Therefore, selecting the right type of thermal printing paper is essential for optimal results.

Thermal printing operates on a fascinating principle that combines heat and special paper. The core of this technology lies in thermal transfer or direct thermal printing. In thermal transfer, a heated ribbon melts ink onto the paper. In contrast, direct thermal printing employs heat-sensitive paper that darkens when exposed to heat. Approximately 80% of receipts and labels produced today utilize thermal printing methods, reflecting its widespread adoption in various industries.

The science behind thermal printing involves precise temperature control and timing. Print heads generate heat at specific points, which creates images or text on the thermal paper. Studies indicate that operating temperatures typically range from 350°F to 400°F. However, this process is not without flaws. Paper quality plays a vital role; low-grade thermal paper can lead to unreadable prints or smudging over time. An estimated 30% of businesses face issues related to print durability and legibility.

Another aspect to consider is the environmental impact of thermal printing. Many thermal papers contain BPA, a chemical that raises health concerns. As regulations tighten, more companies are seeking eco-friendly alternatives. Data suggests that around 60% of consumers are willing to pay more for sustainable products. The balance between efficiency and environmental responsibility remains a crucial topic in the industry.

Thermal printing paper offers several advantages that make it a preferred choice in many industries. One of its key benefits is efficiency. Thermal printers can produce high-quality prints quickly, reducing wait times for both businesses and customers. Reports show that businesses using thermal printing can save up to 30% in time compared to traditional printing methods. This speed can be crucial for point-of-sale systems in retail environments.

Another significant advantage is that thermal printing paper is often more durable than regular paper. It is resistant to fading and tearing, which means printed receipts can last longer. In fact, studies indicate that thermal prints can maintain their quality for several years under proper conditions. However, there are some challenges. For instance, while thermal printing is generally low maintenance, it can be sensitive to heat and light. This may affect the longevity of the prints if not stored correctly.

Cost-effectiveness is also a notable point. Thermal printing paper is often cheaper than inkjet and laser options in the long run. The overall cost per print tends to be lower, and businesses can mitigate waste. Despite these advantages, one must consider potential drawbacks. Changes in humidity and temperature could influence print quality. This calls for careful consideration in environments with extreme conditions.

Thermal printing paper has found a wide array of applications across various industries. It’s most commonly used in retail, where receipts are printed quickly and efficiently. In grocery stores, thermal paper speeds up the checkout process. Customers appreciate the fast service, but some papers fade over time. This can lead to important details being lost.

In the healthcare sector, thermal printing paper is used for medical records and prescriptions. This helps in maintaining accurate patient information. However, reliance on thermal paper has drawbacks. The paper can smudge, hindering readability. Fast-paced environments demand clear communication, yet these limitations can lead to mistakes in vital situations.

Another application is in shipping and logistics. Thermal labels are essential for tracking packages. They provide crucial information for delivery personnel. Mistakes can be costly, and faded labels may contribute to confusion. Industries must balance speed and clarity, especially when dealing with thermal printing paper.